-

About Homer

-

- Americans with Disabilities Act Compliance Program City Campgrounds Community Recreation Hickerson Memorial Cemetery

- Library Parks & Trails Public Safety Fire Police Emergency Information

- Events & Activities City Calendar Library Calendar Recreation Calendar Doing Business in Homer Sister City Program Coast Guard City

-

- Departments

- Government

- How Do I?

Homer Harbor Critical Float System Replacement

Project Description

This project completes design and permitting and replaces two critically deteriorated float systems and gangways in Homer Port and Harbor. The structures range from 38 to 61 years old, no longer meet current design or safety standards and were rated in serious to critical condition in a 2022 Condition Assessment.

Due to the high cost of replacement, estimated at over $60 million, the project has been broken into phases. Phase 1 replaces the 61-year-old portions of Float System 4, now over thirty years past their design life and at risk of partial or catastrophic system failure. The work ensures safe moorage for one-third of the port's 2,192 annual vessels and adds 576 feet of new transient moorage capacity via a new BB float. A future Phase 2 replaces System 1.

Phase 1 Scope

- Complete design and permitting

- Build 36,954 sq ft of floats to replace floats CC, DD, EE and GG and head float AAA, adding 20.2% more capacity to the system with 6,218 sq ft of new floats.

- Bring floats and gangway up to current safety standards.

- Meet ADA accessibility compliance and bring fire suppression, water, and electrical supply systems up to code.

- Expand fairways by extending AAA float and provide additional space to widen too narrow float distances for safe and more efficient maneuvering of larger and mid-size commercial vessels of 40 to 180-foot lengths.

- Add a new BB float with 576 feet of transient moorage and transient power pedestals.

- Replace 102 corroded and undersized pilings and install 31 new pilings.

- Replace a 73-foot gangway with a safer and weather-resilient covered 100-foot gangway.

- Reuse materials where possible, including EE, FF, and GG stall floats (all built in 2002) and the existing gangway trestle.

Phase

![]()

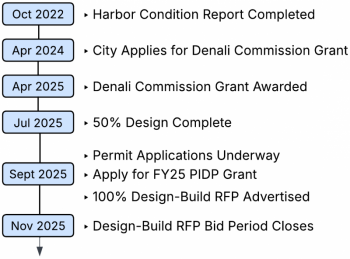

During the execution phase, we will complete design and permitting, followed by procurement, and then construction pending successful Federal grant funding to assist with construction costs.

Cost Estimate

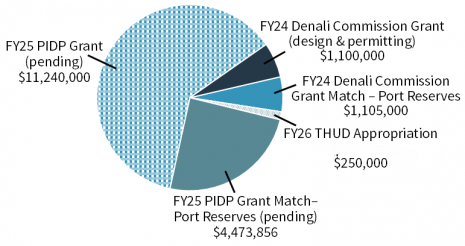

Design $ 2,205,000

Construction $16,418,856

Project Management $ 634,990

Total $19,258,846

Funding

Need and Benefits

Efficient Port Operations: The Harbor currently operates at or above capacity, and demand for moorage and regional freight movement has already outpaced the system's load-bearing capabilities. During spring through fall, vessels are required to raft up to five deep from the floats due to existing space constraints.

Decommissioning floats in Systems 4 and/or 1 would intensify this crisis. System-wide closure would affect 336 vessels in System 1 and 167 in System 4—representing over half the harbor's stall capacity. This loss would severely disrupt Port operations and cause widespread shipment delays throughout the regional freight network. Even closing a single finger float, whether for repairs or permanently, creates a ripple effect that forces affected vessels to raft even further out, hot-berth, relocate to transient moorage, or most likely be displaced entirely from the facility.

Decommissioning an entire float system increases vessel congestion and operational delays related to rafting and tidal draft constraints, cost the harbor and vessel operators time and fuel, and cause life and safety concerns. A sudden float system failure that causes vessel damage would likely cost a fisherman an entire season, incapacitate numerous vessels, slow and disrupt freight delivery schedules, or block access to critical floats and services

Freight Network Reliability: Homer Port and Harbor, which provides moorage, maintenance, and cargo loading services, is a critical link in the marine transportation network supporting vital industries, the Port of Alaska, and 135 non-road connected villages and work sites throughout Southcentral and Western Alaska. Decommissioning float systems will displace vessels, disrupt established supply chains and slow frieght movement.

Key freight operations include:

- Regional freight shipping: Ninety-two vessels provide freight service. One water taxi alone delivers 125 tons of freight monthly to Kachemak Bay communities in summer and 80 tons monthly in winter. A local building materials supplier ships an estimated 1 million pounds of construction materials annually to non-road connected communities.

- Port of Alaska support: Two pilot vessels make 480 trips annually to provide licensed pilots to guide tankers with fuel destined for Ted Stevens International Airport and cargo ships, which handles 50% of all freight shipped to Alaska and serves 90% of the state's population, into the Port of Alaska.

- Commercial fishing industry: Commercial fishing vessels home porting, repairing, provisioning, and delivering in Homer participate in Bering Sea crab, Pacific halibut, Bristol Bay salmon, and other fisheries of national and international significance. Homer ranked as the 78th fishing port in the U.S. by weight and 65th by value, with landings of 4.7M pounds of seafood worth $12.5M in 2020.

- Bristol Bay operations: In 2022, 4 million tons of cargo, 300,000 gallons of fuel, and 350 vessel transports via 25 landing craft originated in Homer Port and Harbor for delivery to Bristol Bay fishing grounds and rural Western Alaska communities throughout the Bristol Bay region.

Safety: An estimated 266,278 people move through the Homer Port and Harbor annually. Over 1,500 boat owners spend 54,582 hours each year walking between the parking lot and their vessels, transferring 13.6 million pounds of freight and supplies—often by hand or cart across uneven, unstable floats. With an average owner age of 59 years, steep gangways (up to 29 degrees at low tide), and slippery conditions, the risk of injury is significant.

An April 2024 vessel owner survey documented 6 incapacitating injuries, 67 minor injuries, and 157 accidents without injuries over the past 10 years—all related to conditions that float replacement will address.The 2022 Condition Assessment documented critical safety deficiencies in Float System 4 requiring immediate action.

The replacement implements specific improvement to address the following safety hazards:

- Inadequate flotation: Disintegrated foam and seawater infiltration have drastically reduced freeboard. Floats submerge under normal adult loads (40 lbs/sq ft) and sink further with winter snow and ice, creating dangerous conditions and exposure to frigid water that freezes the wooden dock surface in the winter.

- Structural instability: Warping, twisting, and listing floats create uneven surfaces that increase fall risk, especially for those carrying cargo or with mobility limitations. Sinking floats also cause gangways to list at dangerous angles.

- Corrosion and failure risk: Saltwater exposure has corroded hinges, bolts, and hardware, making the system highly susceptible to catastrophic failure from boat impacts, high winds, or freezing conditions.